An Eye for Detail: How Lineage Solves for Lack of Standardization in 3PL Receiving

March 21, 2024

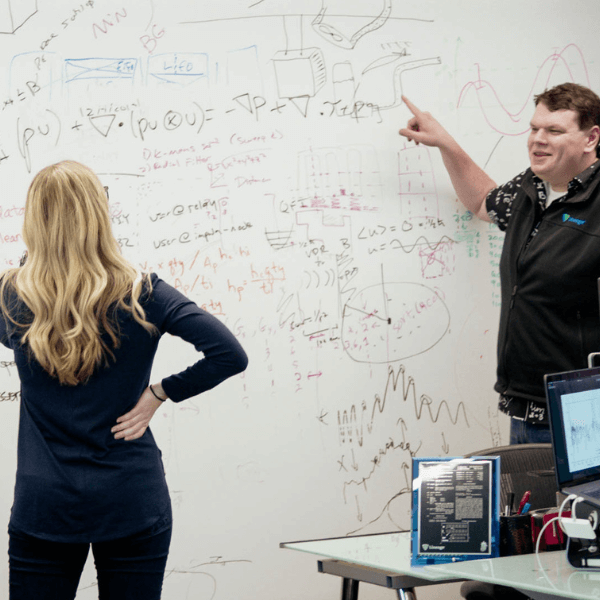

The Central Challenge of Receiving

For an industry that’s built on speed and efficiency, we believe there’s a surprising lack of standardization in the global food supply chain. This is especially true when it comes to the labeling of pallets. “Every one of our 10,000+ customers has their own way of doing things,” says Caitlin Voegele, Director, Data Science Strategy. “Some have bar codes. Some have the important information in text only. Others have selection bubbles you’d find on a test form at school. Anything goes. And we have to handle it all.”

At Lineage this lack of standardization is never an excuse. “It's important to note that it’s up to us to accurately receive every pallet that enters our buildings,” says Elliott Wolf, VP & Chief Data Scientist. “We are the custodians of the inventory. It's not a value-added service. It's not a nice-to-have. When you're in temperature-controlled warehousing it’s important to know what you’ve got.”

No Quick Fixes

Typically, a crew of Lineage team members receives pallets using handheld scanners. But with a typical pallet taking two to five minutes to process, Lineage wanted to find a way to save on time—without sacrificing product quality or food safety. Our data science team turned to automation, approaching vendors to see if they had a solution that could automatically read labels.

Typically, a crew of Lineage team members receives pallets using handheld scanners. But with a typical pallet taking two to five minutes to process, Lineage wanted to find a way to save on time—without sacrificing product quality or food safety. Our data science team turned to automation, approaching vendors to see if they had a solution that could automatically read labels.

“When building our facility in Sunnyvale, Texas, we looked for a robotics company who had the capability for automated receiving and didn’t find any out there, so we went to the system integrator to solve the problem ourselves,” says Daniel Wintz, Director, Warehouse Algorithms. “They were a well-established robotics company and they looked at us like we were absolutely insane. There was no application like this out in the industry.”

A New Twist on a Familiar Feature

Enter Lineage Data Science. Bringing their expertise in computer vision to the problem of processing pallet information, Lineage Data Science built the Lineage Eye, a custom photo booth equipped with four cameras and a turntable. The pallet enters the Lineage Eye via a conveyor belt. Once the pallet is inside, the cameras take 13 pictures that capture the pallet from every angle. These images are then fed through a proprietary software system that extracts label and packaging information using modern computer vision algorithms. This data is compared to the customer’s inventory list to ensure accuracy.

"With modern computer vision algorithms, your phone can take a picture of a take-out menu and automatically extract the phone number,” Brian Leahy, Senior Data Scientist, says. “We're trying to bring that same technology to 3PL receiving at our Lineage Eye facilities."

Setting the Standard

At a fully automated warehouse such as Lineage’s facility in Olathe, Kansas, the impact of Lineage Eye is profound. Because it’s fully automated, most pallets are automatically sent into storage. The few pallets that need more attention are sent to a staging area to be broken down and reconfigured by Lineage team members. Olathe has 38 truck docks that are supported by 6 photo booths. Thanks to the support of the Lineage Eye, team members at Olathe can turn even more trucks per week.

At a fully automated warehouse such as Lineage’s facility in Olathe, Kansas, the impact of Lineage Eye is profound. Because it’s fully automated, most pallets are automatically sent into storage. The few pallets that need more attention are sent to a staging area to be broken down and reconfigured by Lineage team members. Olathe has 38 truck docks that are supported by 6 photo booths. Thanks to the support of the Lineage Eye, team members at Olathe can turn even more trucks per week.

"The beauty of the Lineage Eye is that it works on real pallets at real warehouses without requiring additional preparation of the pallet,” Leahy says. “This helps the facility work more quickly and efficiently. It also frees up team members to solve higher order problems for our customers.”

Lessons in Automation

Going forward, Leahy is working on ways to bring the Lineage Eye to legacy facilities. For the Lineage innovation team, this initiative is a model for how to get the most out of both technology and people.

“Our vision is to solve hardware problems with hardware, software problems with software,” says Wolf. “And never forgetting the human element.”

For more information on Lineage Eye, go in-depth with our free, flowable PDF.